fuck CO2

CO2-negative materials in high quality and at low prices.

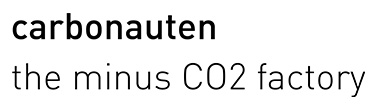

carbonauten develops and produces industrial precursors and raw materials based on biocarbons and bio-oils in decentralized factories. The biocarbons permanently physically bind up to 3.67 tons of CO2 equivalent per ton of biocarbon. The bio-oils are a by-product and serve as a CO2-negative raw material for the chemical industry. Another by-product is base-load-capable renewable energy.

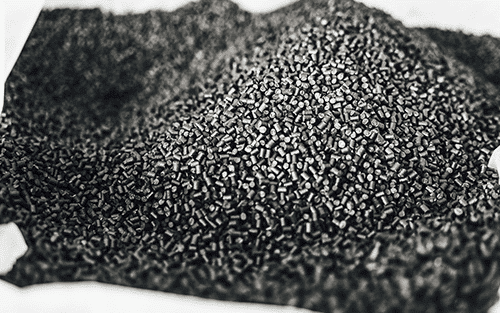

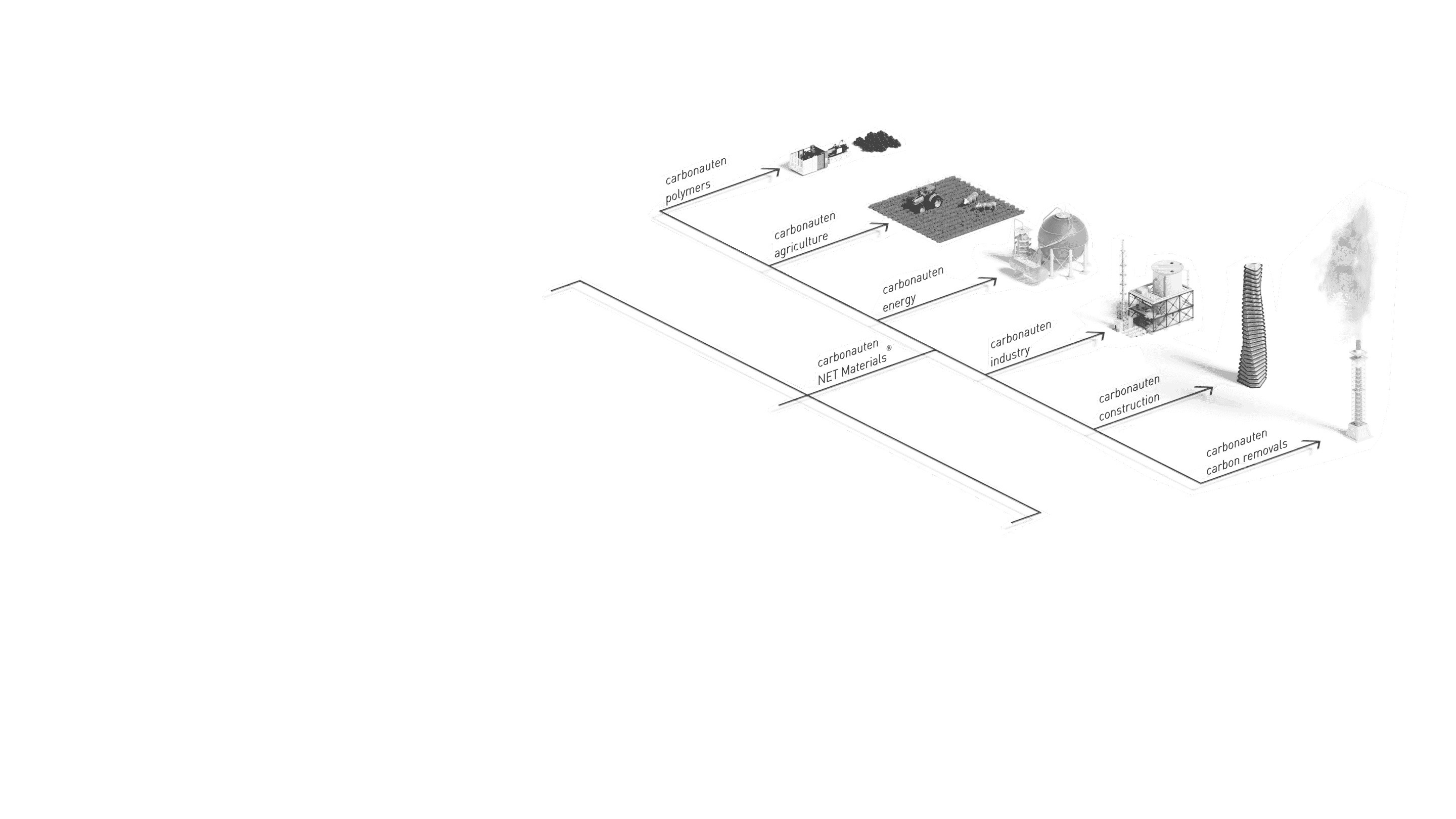

carbonauten has developed its own industrial and robust carbonization technology that can flexibly process all types of woody biomass residues. The biocarbons are processed in the factories into a new category of materials, the “NET Materials®” (Negative Emission Technology). They are CO2-negative precursors for the plastics, chemical, agricultural and construction industries.

carbonauten produces NET Materials® in large quantities and at low prices to make decarbonization economically attractive for the industry with an impact also in Scope 3.

Six sectors for CO2-reducing activities

Agriculture

→ Livestock farming, soils, plants

Energy

→ Heat, electricity, hydrogen

Polymers

→ Masterbatches, Compounds

Chemistry

→ Platfrom chemicals from waste materials

Construction

→ Various CO2 sinks

Carbon Removal

→ Ecological and profitable

How does it work?

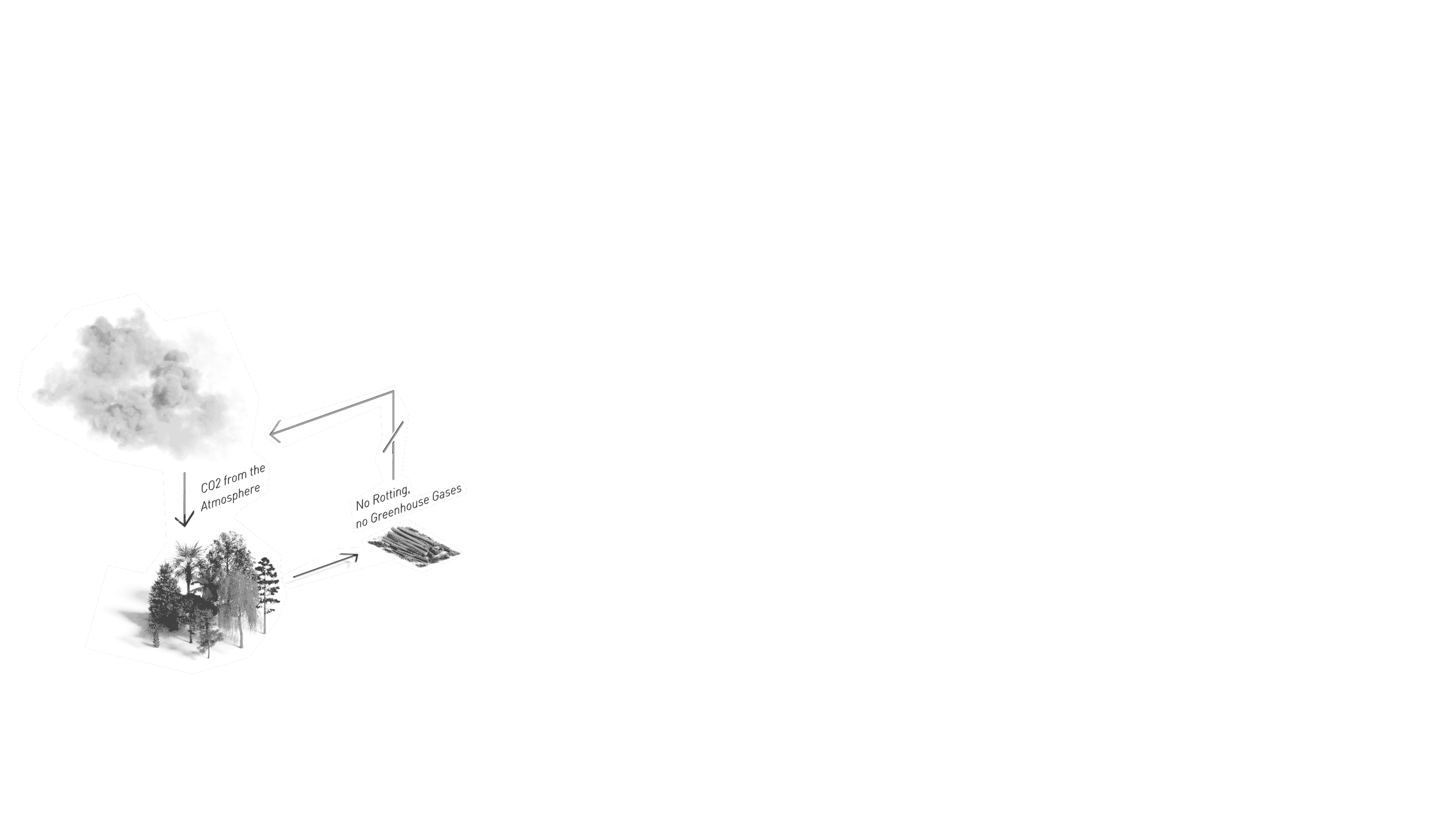

Carbon (C) is the basis for organic life in the universe. It occurs bound in solid or gaseous form – as carbon dioxide CO2. Plants have been the most efficient and beautiful CO2 storage machines for millions of years. They use the carbon contained in CO2 to build up their biomass through photosynthesis and release the oxygen into the atmosphere.

A tree consists of about 50% carbon. At the end of its life, it is metabolized by microorganisms. This releases the greenhouse gases carbon dioxide, methane and nitrous oxide.

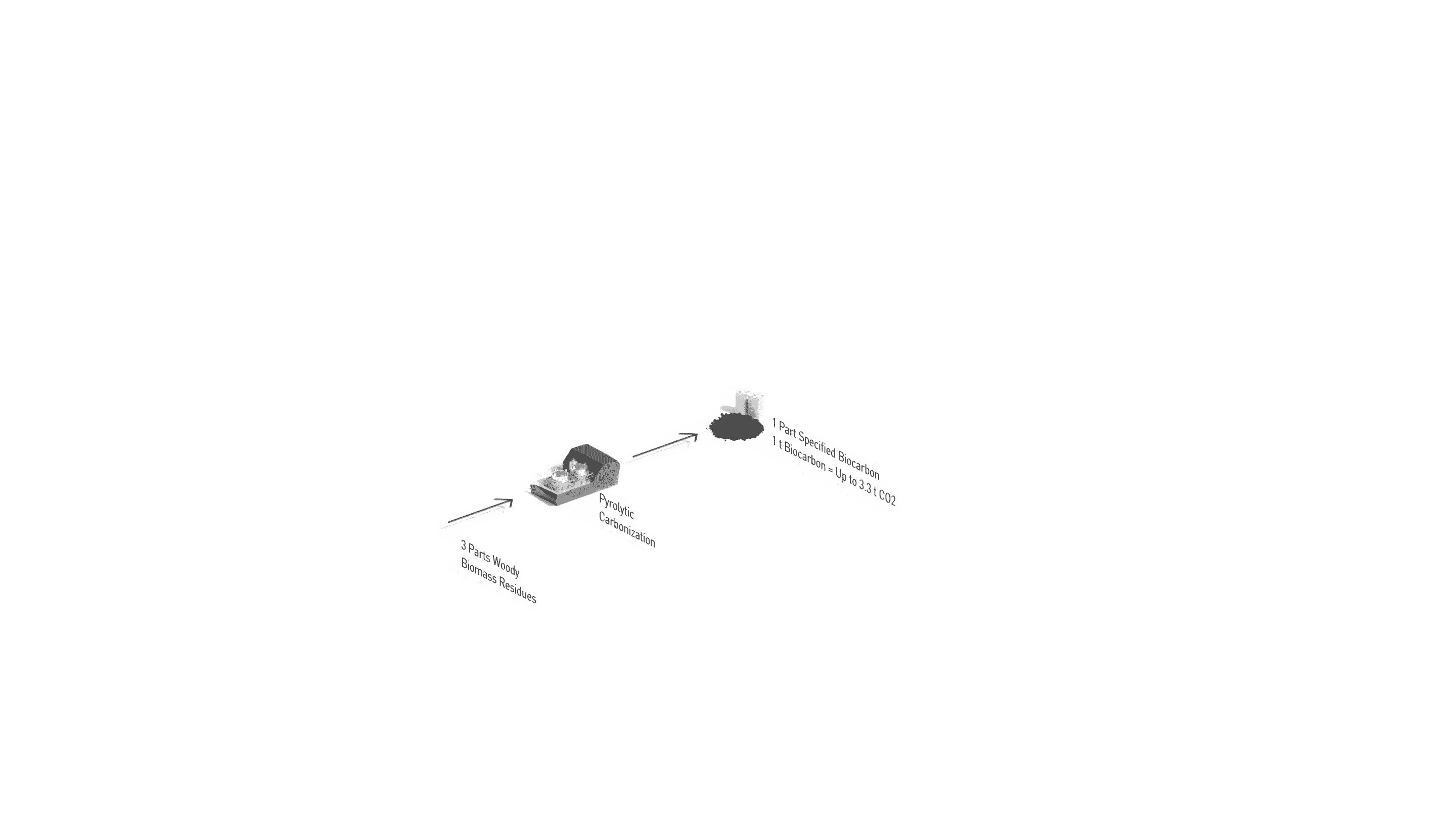

This metabolization process is stopped through pyrolytic carbonization (heating without acces to oxygen) between 400° and 700° C.

This produces physically and chemically stable biocarbons that no longer biodegrade and thus permanently prevent the production of greenhouse gases.

With carbonauten’s proprietary pyrolysis technology, wood residues are broken down into the three basic materials biochar, pyrolysis oil and synthesis gas.

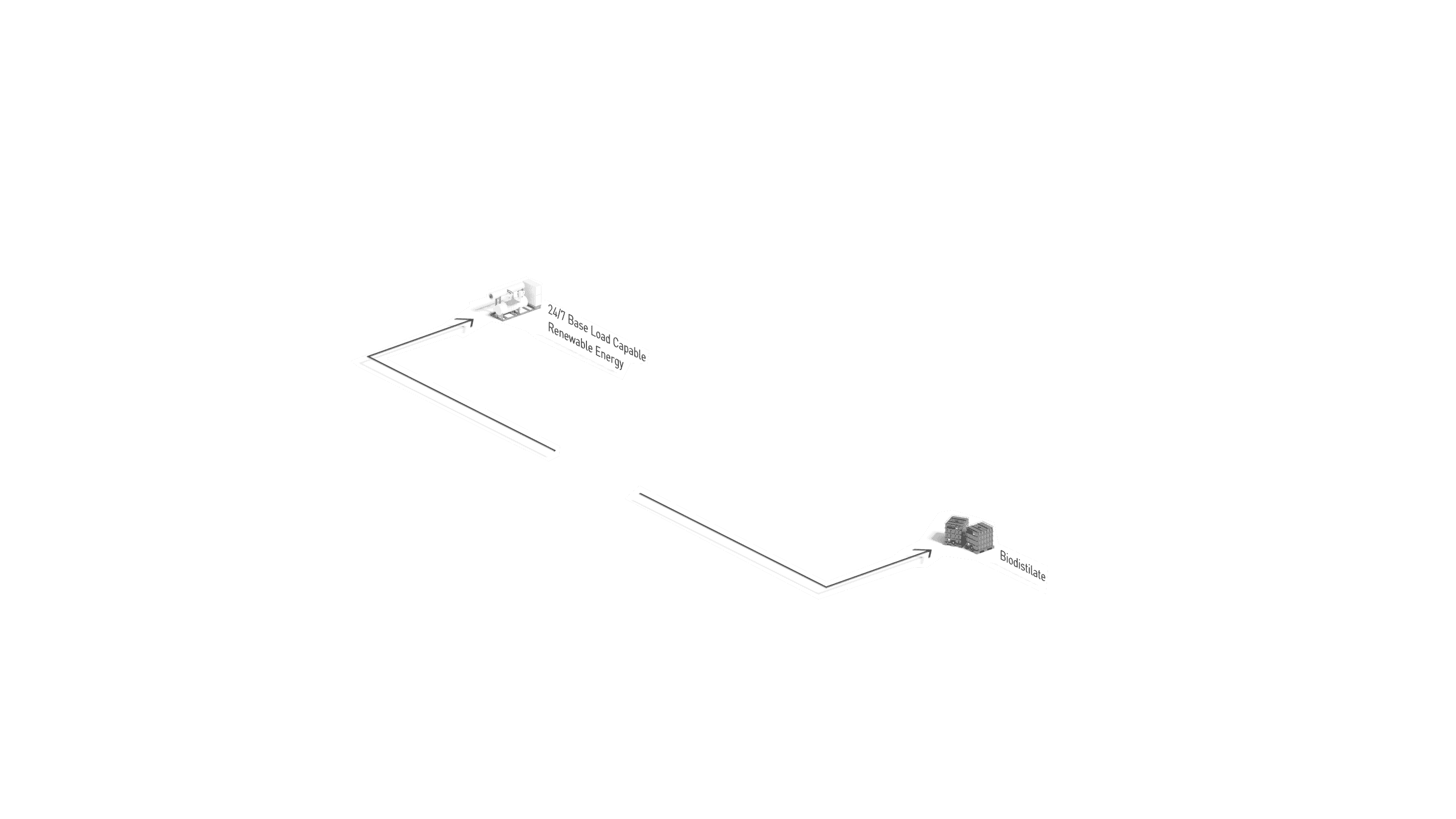

The biochar is then refined in the minus CO2 factories into NET-Materials® for various markets and applications. The pyrolysis oils, which are also CO2-negative, are separated and further processed by third parties. The synthesis gas is used for the factories’ own needs (electricity, heat) and the surplus is sold to third parties as base-load-capable, renewable energy.

That way, the carbonauten system enables the material and energetic cumulative use of biomass residues and a maximized value chain.

.

The carbonauten system creates multiple effects

The most recent from the minus CO2 factory

CO2-negative parts for the ICE

For the first time, seat shells and armrests of the ICE were injection molded from CO2-negative plastic with a biocarbon content of 33%....

Construction of minus CO2 factory 002 begins in Chibi, China

On 7 November 2023, carbonauten GmbH started construction of the world's largest carbonisation plant for the extraction and storage of CO2...

What characterizes a carbonaut? (2/2)

Continuation of the previous blog post. We keep talking. About money, politics and vision. Aaron: You mentioned funding issues earlier. In...

minus CO2 factories – the industrial solution to fight CO2

Maximized value chain and living laboratory

The active reduction of CO2 starts at the “minus CO2 factory 001” in Eberswalde near Berlin. It is the first of what will be dozens of factories worldwide. In addition to industrial production, Eberswalde is a research and development location for hardware, technological enhancements and optimization of production processes.

International scaling is being driven forward at the headquarters in Giengen an der Brenz. In the medium term, the site will be expanded for the development of new NET Materials® applications.

Harmonization of industry, ecology and society

carbonauten NET-Materials® enable industry to add value to products economically, ecologically and socially, thus growing sustainably and making a positive contribution to society.

In-house technology to reduce gigatons of CO2

carbonauten will be building and operating decentralized sites worldwide from 2025. The flexible, robust and modularly expandable carbonization technology regarding input and output is the result of many years of experience and technical expertise in the carbonization of biomass residues and energy generation. By 2040, global production sites with annual capacities of between 10,000 and 50,000 tons of biocarbons, pyrolysis oils and renewable energy can avoid greenhouse gases in the gigatonne range via Scope 3 and thus make materials, food and energy renewable, better and cheaper for everyone.